E-Invoicing and Its Geopolitical Stakes

France’s electronic invoicing reform relies on a Y-architecture, where Partner Dematerialization Providers (PDPs) play a central role in issuing and…

Generix Announces the Appointment of Olivier Vaillancourt as General Manager for North America View the press release

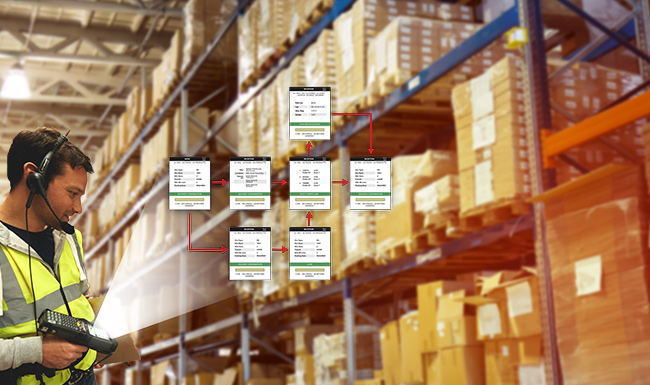

The WMS’ ability to integrate with corporate information systems is essential, as is its ability to adapt to many other systems, including ERPs, CRMs, etc. By integrating into the heart of a company’s technology and supply chain processes, the WMS becomes a powerful tool in driving performance.

The lifespan of a typical WMS is 10 to 15 years. Its ability to evolve is crucial to ensuring the execution of the company’s development strategy: new products, e-commerce / omnichannel, multi-site deployment, etc. The system’s scalability is measured in terms of order volume and complexity, processes managed, permitted use cases, new process integrations, and the extent of visibility provided.

End-to-end supply chain management directly contributes to improving a company’s productivity. If the WMS and the integration partners are fully connected to the supply chain information system, real-time 360-degree visibility will be met. The flexibility of having a SaaS deployment option makes this all possible.

Integration with warehouse equipment systems (WES), mobility, augmented reality solutions that optimize selection, and data analytics for better decision making should be considered. These features, offered by next-generation WMS solutions, boost productivity and efficiency in the warehouse.

SaaS is becoming increasingly popular in new WMS deployments for many reasons: easy and fast implementation; pay-per-use; scalability; lack of upfront investment, maintenance, or upgrade costs; IT investments transferred from CAPEX to OPEX. Although the total cost of ownership (TCO) is lower in SaaS, both deployment models need to be compared for any new project.

A successful WMS project is not only about choosing the right product, but it also factors in the ability of the vendor to meet the needs of the company. In addition to its financial strength, it is essential to pay attention to other critical aspects of the vendor: business process expertise, confirmed experience of similar deployments, the know-how of multi-site / international deployments, post-implementation service offerings, significant R&D investments, etc.

To be successful, a new WMS project requires a structured approach. It usually comprises two main stages: the strategy phase and the selection phase. The company must carefully map its business processes, rules, exceptions, goals, and strategies to enable vendors to formulate the best replies to RFIs and RFPs.

France’s electronic invoicing reform relies on a Y-architecture, where Partner Dematerialization Providers (PDPs) play a central role in issuing and…

The B2B mandate in Germany, set to take effect on January 1, 2025, marks a crucial step in the European…

Following the October 15 announcement regarding the abandonment of the PPF development, the DGFIP and its partner AIFE are ramping…

Work with our team to build your ideal supply chain software stack and tailor it to your unique business needs.