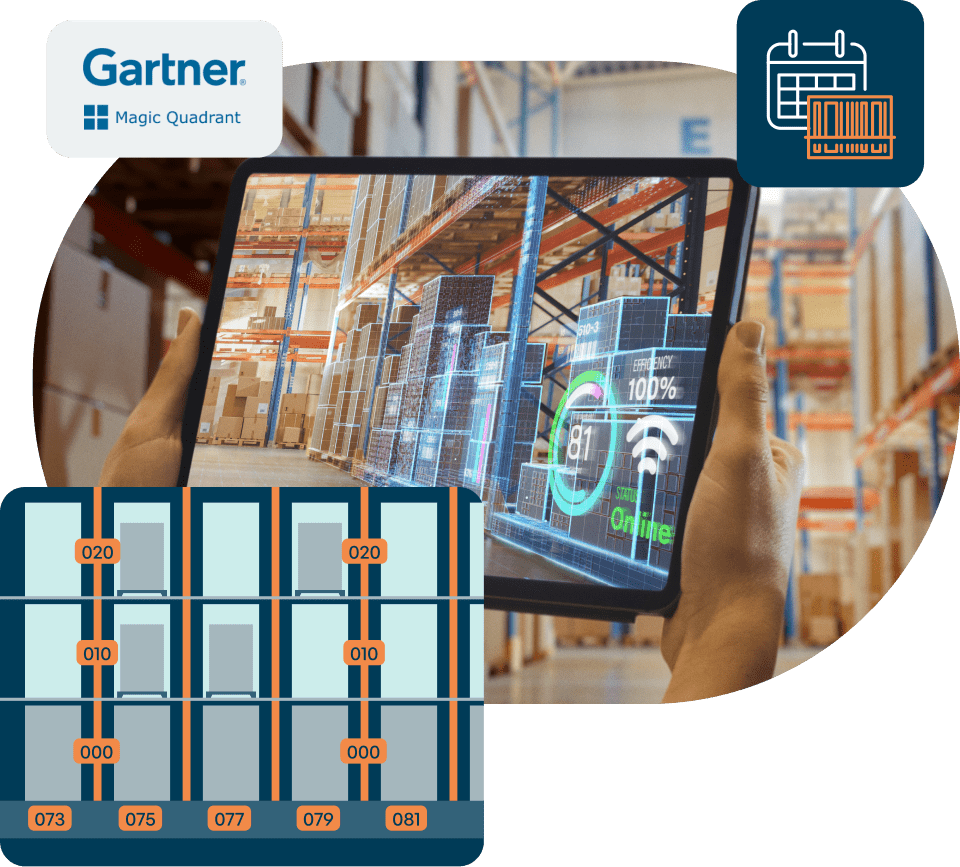

Warehouse Management System

A flexible, usable and affordable WMS designed for quick time-to-value

Enjoy a modern feature-rich WMS system, that makes it easy for logistics, distribution, and fulfillment to quickly configure their WMS to meet their current and future operational requirements.